Rotating Nozzle PRD 3500 LV

Rotating nozzle PRD 3500 LV – light, small, perfect for surface finishing, especially for concrete restoration, decoating, paint and varnish removal

The rotating nozzle type PRD 3500 LV is suitable for both gun operation and other manipulators due to rotary movement of the nozzle head. It is ideally suited for surface cleaning and renovation. This includes, in particular, concrete restoration, decoating and removal of paint and varnish. The rotation insures an even and streak-free cleaning of large surfaces. The speed is regulated with an adjustable eddy current brake.

Rotating nozzle type PRD 3500 LV in new design – lightweight, small and easy to maintain

The abbreviation LV in the name of the nozzle stands for light version. The name makes it clean what has been achieved with its re-design. The new rotating nozzle is shorter and smaller in diameter. The technical changes make it not only lightweight but also easier to maintain and handy to use. The previous version used to weigh 1.6 kg, not it weighs only 1 kg without the nozzle head. Completed with a nozzle head, it used to weigh 2.25 kg and now the total weight is only 1.55 kg. Not only the housing is now much narrower, but there is also a new variety of exchangeable nozzle heads (DK). There are four nozzle heads in total (DK1 to DK4), divided into two groups. There are two larger nozzle heads (DK1 and DK2) and two new smaller nozzle heads (DK3 and DK4). These nozzle heads cover all spray gun operations from cleaning or removing large surfaces to spot jetting work.

Smaller diameter of nozzle head variants makes PRD better for small corners

For example, the DK4 delivers 30 l/min at 1000 bar to an area, which is a lot of volume particularly suitable for concrete restoration. In contrast, the two small DK1 and DK2 are best suited for paint stripping or decoating and therefore are used with our mobile high-pressure unit KamJet with 20 l/min and 3,000 bar. The smaller nozzle diameter achieved by the re-design also makes them more suitable for hard-to-reach places. The diameter of only 55 mm is particularly useful for cleaning small corners. Another advantage of the recent re-design is the easy maintenance. It only takes 15 minutes to change the wearing parts kit with a seal, shaft and bearing. Last but not least, changing the nozzle head is also much faster now.

Technical Specifications

- max. working pressure 3,500 bar

(350 MPa) - max. flow rate 50 l/min

- min. – max. speed 1000-4000 Upm

max. fluid temperature 90 °C - length total 181 mm

- outer Ø total 55 mm

- weight incl. nozzle head model

1,55–1,65 kg - weight excl. nozzle head model 1,00 kg

- hp-connection autoclave M 26×1.5

- no. of nozzle inserts min.- max 3-6

- usable nozzle inserts straight jet screwed nozzles type 0964

Special Features

- the rotating nozzle achieves an even surface cleaning without streaks, due to its rotation

- adjustable RPM because of the built-in eddy current brake

- nozzle head and swivel joint are made of high tensile aluminum & stainless steel

- compact, easy maintenance and long lifetime

- leak-free

- change of nozzle head without tool

Additional Literature

Our Company

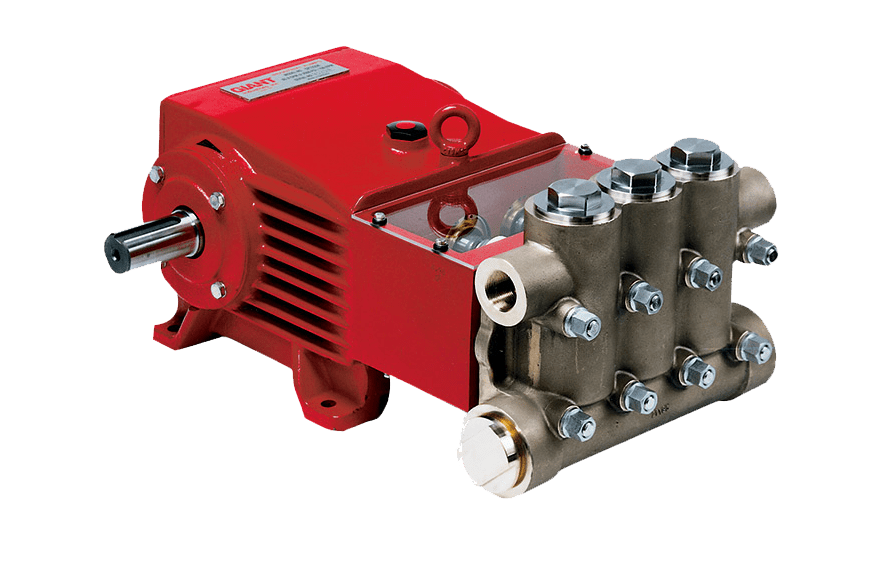

For 50 years, Giant Pumps has offered the most dependable positive displacement high-pressure triplex pumps available. Designed and built to the highest quality standards, customers count on Giant Pumps products to keep their equipment running. Every design detail of Giant Pumps products is optimized for long-life and reliable performance, making Giant Pumps the most trusted name in high-pressure pumps and systems.