High Pressure Filters

Reliable filtration and ecology-minded water treatment

Powerful filter technology for a clean environment

The in-house KAMAT filter technology is innovative and fast-growing. Why are we also involved in the field of filter technology? The answer is simple: high-pressure cleaning technology with the environmentally friendly medium water requires a high-quality filter and recycling solution. In some cases, classic filter manufacturers cannot meet these requirements, so that KAMAT also offers its own customer-specific solutions in the field of filter technology.

Customer-specific high-pressure filter solutions for filter technology

High-pressure cleaning technology with water has many advantages: A water jet can be used gently on the surfaces to be cleaned, water is generally available as a medium and is, at the same time, environmentally-friendly without extensive delivery outlays. Regarding accessories, high-pressure cleaning systems generate special requirements, which are difficult to meet. For this reason KAMAT has developed its own customer-specific, high-pressure, filter solutions.

For the protection of sensitive parts in high-pressure cleaning systems and diesel injectors

KAMAT high-pressure filters are available for operating pressures up to 4,000 bar. The task of the filter is the protection of both the sensitive high-pressure component parts, and the material to be processed. The water may contain hard particle contamination, for example in recycled water or in industrial water. This hard particle contamination could impair the water tools, such as high-pressure nozzles and rotating joints, in the long run. High-pressure filters are additionally used in order to protect fuel injectors, for instance in large diesel engines.

KAMAT offers water-recycling systems and cleaning technology which match the high-pressure filters. They provide for an environmentally-friendly recycling of the water jet in cleaning applications.

Of course, we also take over the complete installation and commissioning of all systems on site on request.

Technical Specifications

- max. flow (water) 50 l/min

- max. temperature 150 °C

- max. differential pressure 150 bar

- total length 205 mm

- outer diameter 150 mm

- connection M 26×1.5

(autoclave hp-fitting with

pressure ring M 14×1.5 LH and

pressure screw M 26×1.5) - weight 14.6 kg

Special Features

Design

- stainless steel housing without filter insert

- reworkable, metal-to-metal sealing system

- transparent spray protection

- FDA/GMP suitability

Fluids

- water, saline and demineralized

- non-aggressive chemical fluids

- biotechnological suspensions

- solutions (e.g. acetone)

- viscosity up to 2,000 mPas

Additional Literature

Our Company

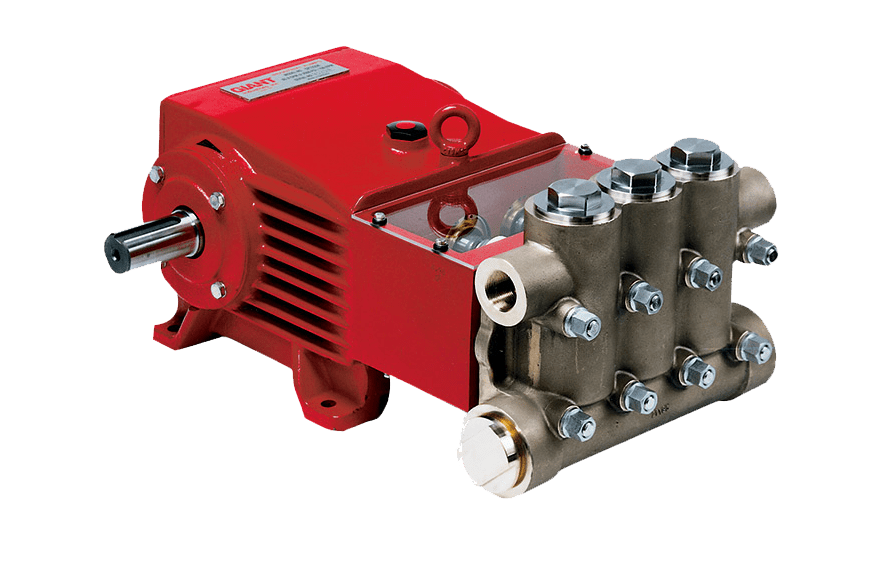

For 50 years, Giant Pumps has offered the most dependable positive displacement high-pressure triplex pumps available. Designed and built to the highest quality standards, customers count on Giant Pumps products to keep their equipment running. Every design detail of Giant Pumps products is optimized for long-life and reliable performance, making Giant Pumps the most trusted name in high-pressure pumps and systems.