22983

Pressure-actuated valves control the flow of the water to the nozzle(s). During bypass mode, all of the water is directed back to the supply at nearly zero pressure. This valve is typically used in applications in which frequent on/off action is required at the nozzle, such as; pressure washer, central cleaning station or hydro-excavation. While slightly different design concepts are used, these unloaders typically will actuate at 5 to 20% above the operating pressure of the system.

Flow ranges are from 0.5 GPM (2 l/min) to 625 GPM (2366 L/min) and pressure range is from 100 PSI to 50,750 PSI (7 to 3500 Bar). In lower pressure applications, a manually adjusted spring is used to control the flow; however, pneumatic and electric controls can also be used. Typical metal materials are forged brass, 303 stainless steel, 316 stainless steel and elastomers will be either Nitrile, Viton or Teflon.

For individual specifications see below.

WARNING: This product might contain a chemical known to the State of California to cause cancer, and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

| Specification | US | Metric |

|---|---|---|

| Minimum Flow | 2.1 GPM | 8 L/min |

| Maximum Flow | 66 GPM | 250 L/min |

| Min Pressure | 200 PSI | 14 bar |

| Max Pressure | 800 PSI | 55 bar |

| Temperature Rating | 190 °F | 88 °C |

| Inlet Port | 1" BSP | |

| Outlet Port | 1" BSP | |

| Bypass Port | 3/4" BSP | |

| Weight | 15.4 lbs. | 7 kg |

| ITEM# | PART# | DESCRIPTION | Qty. |

|---|---|---|---|

| Plunger Packing Kit – Part #09578 | |||

| 14 | 13247 | Piston | 1 |

| 15 | 13248 | Seal Support | 1 |

| 16 | 12021 | Hexagon Nut | 1 |

| 18 | 13012 | O-Ring | 1 |

| 20A | 07281 | O-Ring | 1 |

| 21 | 07840 | Support Ring | 1 |

| 21A | 13253 | Support Ring | 1 |

| 22 | 13254 | Seal Pack | 1 |

| 22A | 13255 | Seal Pack | 1 |

| 23 | 13256 | Valve Seat | 2 |

| 25 | 12057 | O-Ring | 2 |

| 26 | 12055 | O-Ring | 1 |

| 28B | 07653 | O-Ring | 1 |

| 29 | 13260 | Valve Plate | 1 |

| 30 | 07750 | Valve Spring | 1 |

Materials

Our Company

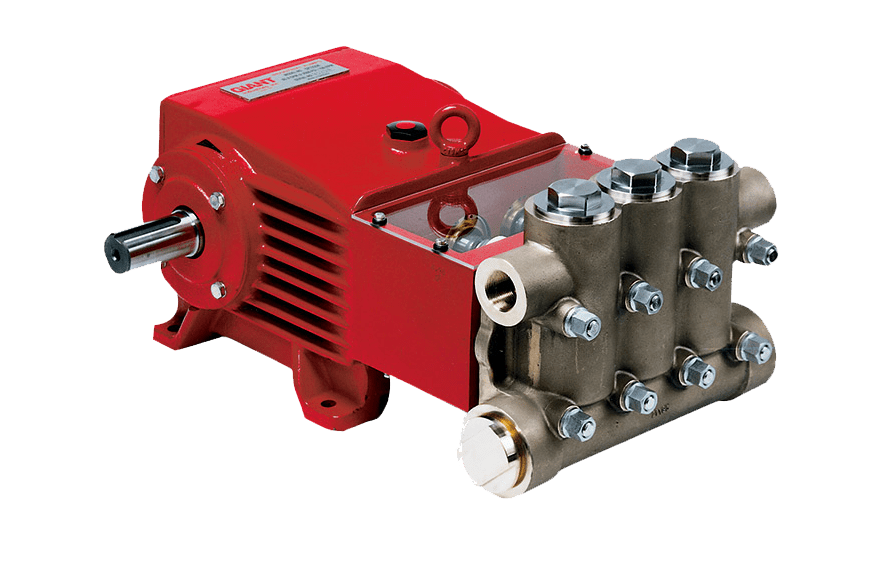

For 50 years, Giant Pumps has offered the most dependable positive displacement high-pressure triplex pumps available. Designed and built to the highest quality standards, customers count on Giant Pumps products to keep their equipment running. Every design detail of Giant Pumps products is optimized for long-life and reliable performance, making Giant Pumps the most trusted name in high-pressure pumps and systems.